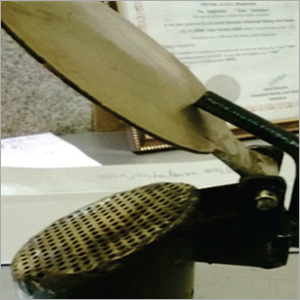

Rain Caps Flapper

Price 750.00 INR/ Unit

Rain Caps Flapper Specification

- Bend Radius

- Fixed

- Tensile Strength

- 350 MPa

- Flexibility

- Rigid

- Tolerance

- 0.05 mm

- Diameter

- 150 mm

- Coating Type

- Zinc Coated

- Connection Type

- Clamp Mount

- Sealing Type

- Gravity Flap

- Temperature Range

- -20C to 400C

- Yield Strength

- 255 MPa

- Product Type

- Rain Caps Flapper

- Material

- Galvanized Steel

- Connection

- Clamp-On

- Shape

- Round

- Standard

- ASTM A653

- Surface Treatment

- Hot Dip Galvanized

- Outer Diameter

- 150 mm

- Section Shape

- Circular

- Length

- 120 mm

- Thickness

- 2 mm

- Color

- Silver

- Usage

- Flue Pipe Protection

- Rated Pressure

- Atmospheric

- Material Grade

- G90

- Application

- Industrial Chimney, Exhaust, Ventilation Systems

- Weather Resistance

- Yes

- Package Includes

- 1 x Rain Cap Flapper

- Installation Method

- Clamp-On, No Tools Required

- Noise Dampening

- Yes

- Opening Mechanism

- Weighted Flapper

- Corrosion Resistance

- High

Rain Caps Flapper Trade Information

- Minimum Order Quantity

- 1 ,

- Supply Ability

- 100 Per Week

- Delivery Time

- 1 Week

About Rain Caps Flapper

Our dedicated professionals continuously work in order to provide the best quality Rain Caps Flapper. The offered caps are manufactured by our experts using supreme grade materials in accordance with defined industry norms. These are utilized to discharge termination construction for a upright pipe, tube or stack comprising a pivoted flapper to typically shut the end of said discharge termination construction as well as no less than one downwardly inclining typically enclose to the air side pipe slanted to release normally upstream. The offered caps are machined to an exceptional tolerance level, with rolled threads for increased strength. Moreover, these Rain Caps Flapper are properly tested on diverse measures to ensure their best quality at customers end.

Features of Rain Caps Flapper :

- Highly durable

- Seamless finish

- Excellent strength

Material of Assembly Provided: Alloys, stainless steels and C.S. Alloy Steels

Manufacturing Range: 1/2 to 24

Superior Protection for Exhaust Systems

Engineered for both durability and performance, this rain cap flapper prevents rain, debris, and pests from entering your exhaust or chimney systems. Its weighted flap operates smoothly, automatically opening to release gases when needed and sealing tightly during downtime, ensuring consistent system function and extended lifespan.

Simple, Tool-Free Installation

Installing this rain cap is remarkably convenient thanks to its clamp-on design. There is no need for special tools or additional hardware, reducing installation time and effort. Just position and secure the rain cap onto the pipe endits precise fit and gravity flap design guarantee a reliable connection and performance over time.

Reliable Durability in Harsh Conditions

Manufactured from G90 grade galvanized steel and built to ASTM A653 standards, the rain cap boasts exceptional corrosion and weather resistance. The zinc-coated, hot dip galvanized surface ensures the cap remains resilient across a wide temperature range (-20C to 400C), making it a robust choice for industrial settings.

FAQs of Rain Caps Flapper:

Q: How is the Rain Caps Flapper installed onto pipes or chimneys?

A: The rain cap features a clamp-on connection, allowing for quick and tool-free installation. Simply position the cap over the pipes end (150 mm diameter), tighten the integrated clamp by hand, and ensure it is securely fitted. No specialized tools or equipment are needed.Q: What materials are used in the construction of the Rain Caps Flapper?

A: This product is manufactured from galvanized steel of grade G90, adhering to ASTM A653 standards. It has a hot dip galvanized, zinc-coated surface for high corrosion protection and a robust, rigid structure.Q: When should I use a Rain Caps Flapper for my exhaust or ventilation system?

A: Install a rain cap flapper when you need to protect flue pipes, industrial chimneys, or ventilation ducts from rain intrusion, debris, and pests, while also minimizing noise and maintaining proper exhaust flow. It is particularly beneficial in outdoor or industrial settings.Q: Where can the Rain Caps Flapper be used effectively?

A: The rain cap is ideal for use on industrial chimneys, flue pipes, and ventilation systemsanywhere external pipe openings require protection from environmental elements across a temperature range of -20C to 400C.Q: What is the benefit of the weighted gravity flap opening mechanism?

A: The weighted flapper opens automatically under the force of rising exhaust gases, ensuring efficient ventilation. When the system is inactive, gravity keeps the flap closed, providing a secure seal against rain, noise, and unwanted entry of foreign objects.Q: How does the rain cap contribute to noise dampening?

A: The design incorporates features that reduce noise transmission through the flue or chimney opening by providing a snug fit and a weighted flap, which helps dampen vibration and prevent the clattering of loose caps during windy conditions.Q: What process ensures the rain caps high corrosion and weather resistance?

A: The rain cap undergoes a hot dip galvanizing process for its coating, which provides robust zinc protection and meets ASTM A653 and G90 material standards. This treatment ensures outstanding resistance to weathering and corrosive industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flappers and Caps Category

Brass Rain Cap

Price 750.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Golden

Tolerance : 0.05 mm

Tensile Strength : 350 MPa

Flexibility : Rigid

Send Inquiry

Send Inquiry