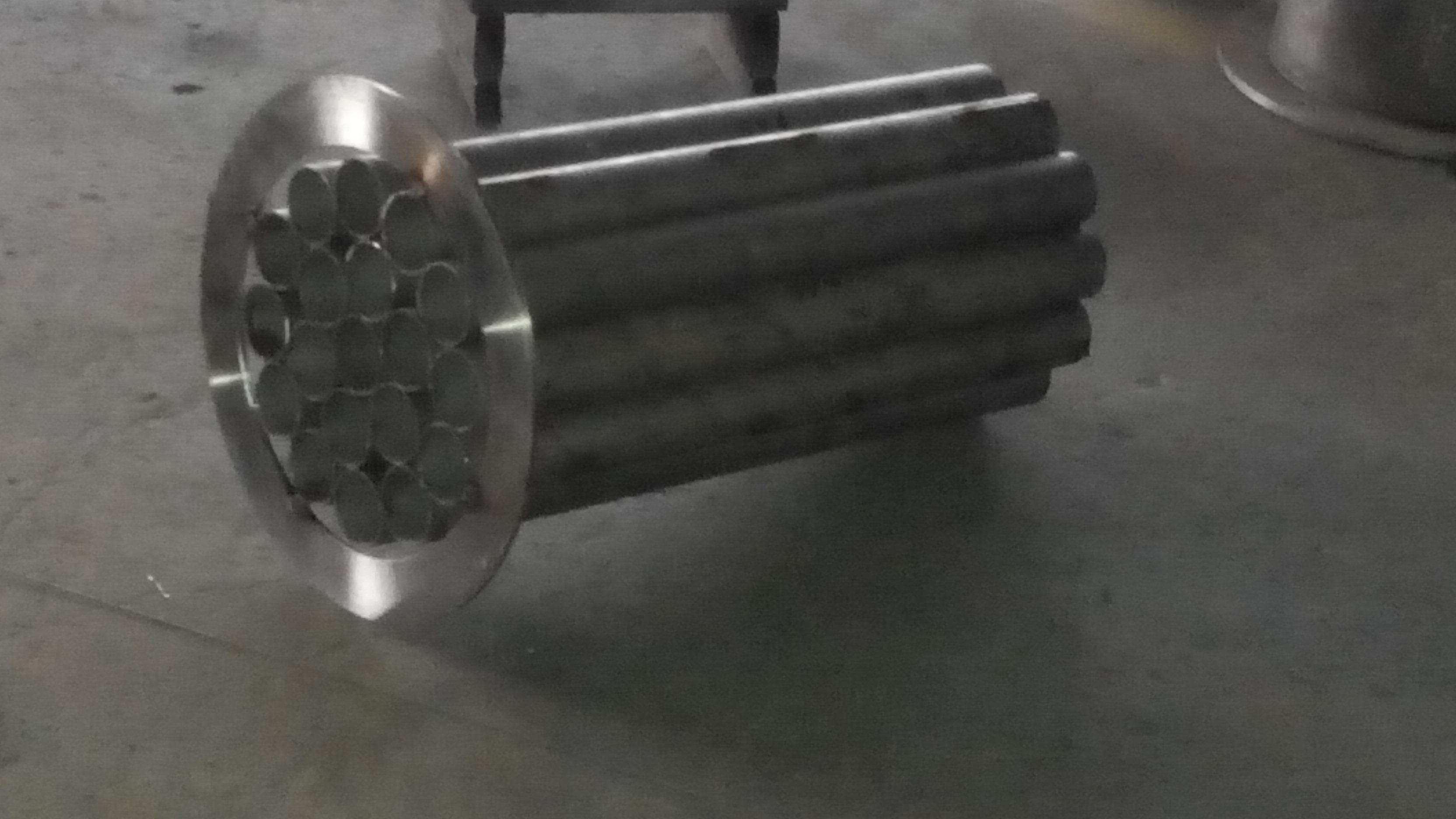

Flow Straightener

Flow Straightener Specification

- Temperature Range

- -20C to +200C

- Yield Strength

- 110 MPa (Al) / 210 MPa (SS)

- Tensile Strength

- 240 MPa (Al) / 520 MPa (SS)

- Diameter

- 100 mm

- Coating Type

- Corrosion Resistant

- Connection Type

- Flange

- Tolerance

- 0.1 mm

- Sealing Type

- Gasket Sealed

- Flexibility

- Rigid

- Product Type

- Flow Straightener

- Material

- Aluminum / Stainless Steel

- Connection

- Flanged

- Shape

- Cylindrical

- Standard

- DIN/ISO Standard

- Surface Treatment

- Anodized / Polished

- Outer Diameter

- 100 mm

- Section Shape

- Honeycomb/Core Grid

- Length

- 150 mm

- Thickness

- 2 mm approx.

- Color

- Silver / Metallic Grey

- Usage

- Used in fluid systems for flow conditioning

- Rated Pressure

- Up to 10 Bar

- Application

- Water, Air, and Industrial Liquid Flow Control

- Material Grade

- SS304 / SS316 / Al6061

- Maximum Flow Rate

- Up to 2500 LPH

- Corrosion Resistance

- High

- Custom Sizes Available

- Yes

- End Connection Size

- DN100

- Cleaning

- Removable and washable

- Installation Method

- Inline

- Weight

- Approx. 0.45 kg

- Maintenance

- Low

- Grid Cell Size

- 6 mm

- Packaging Type

- Box

Flow Straightener Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 1 Week

About Flow Straightener

We are widely accepted name in global market for exporting and supplying the best quality array of Flow Straightener. It is is an instrument installed at upward throat of metering and measuring equipment for reason of arrangement in speed of media to create circulation parallel for precise metering and measuring. It has additional resistances to thermal and corrosive damage. Available in different specifications, this is manufactured under the vigilance of our team. In addition, this Flow Straightener can be purchased from us at market-competent prices.

Features of Flow Straightener:

- Weather resistance

- Easy to install

- Robust construction

- API -14.3

- AGA-3

Sorts of our flow straighteners provided by our company:

- Flow Conditioning Plates

- Flow Straightening Vanes

- Making of flow Straightening Vane

- 7 Tube pack for 2'' pipe

- 19 Tube pack for 3'' & more

Production Scope: 2" to 36"

Product Specification

| Application Media | Any Liquid |

| Brand | Nuseal |

| Line Size | 2" to 60" |

| Model | Nupros Flow Straightener |

| Flow range(Min-Max) | As per Client Requirement |

| Operating Pressure | As per Client Requirement |

| Operating Temperature (Celsius) | As per Client Requirement |

| MOC | SS 304 and SS 316 |

| Pressure rating | ANSI 150# to ANSI 2500# |

Optimal Flow Conditioning

Our Flow Straightener is engineered to deliver uniform streamlines in fluid systems, reducing turbulence and promoting steady flow. The honeycomb/core grid shape with 6 mm cell size straightens the flow efficiently, enhancing the performance and longevity of downstream equipment such as meters and valves.

Durable Construction for Demanding Environments

Fabricated using premium stainless steel (SS304, SS316) or high-grade aluminum (Al6061), this flow straightener delivers remarkable resistance to corrosion and carries a surface thats either anodized or polished. Designed to withstand pressures up to 10 bar and wide temperature extremes, it offers consistent reliability in various industries.

Maintenance Made Simple

With a removable and washable design, maintaining the Flow Straightener is straightforward and cost-effective. Its low-maintenance structure and robust gasket-sealed flanged connection help minimize downtime, while the sturdy honeycomb grid assures structural integrity during routine cleaning operations.

FAQs of Flow Straightener:

Q: How is the Flow Straightener installed in a fluid system?

A: The Flow Straightener is designed for inline installation and features flanged end connections (DN100, outer diameter 100 mm) with gasket sealing, ensuring secure and leak-tight integration within your pipeline or fluid system.Q: What are the key benefits of using this Flow Straightener?

A: It delivers consistent flow conditioning, significantly reduces turbulence, enhances measurement accuracy for flow meters, and decreases wear on downstream components. Its high corrosion resistance and durable construction make it suitable for challenging industrial environments.Q: When should the Flow Straightener be cleaned or maintained?

A: Due to its low-maintenance design, periodic cleaning is recommended when there is noticeable performance drop or buildup observed. The removable and washable grid makes the maintenance process easy and efficient, typically during scheduled downtime.Q: Where can the Flow Straightener be applied?

A: Its suitable for water, air, and industrial liquid applications, commonly used in process plants, filtration systems, and flow control setups requiring maximum flow rates up to 2500 LPH and pressures up to 10 Bar.Q: What materials and grades are available for the Flow Straightener?

A: Options include high-grade stainless steel (SS304 or SS316) and aluminum (Al6061), each providing excellent corrosion resistance and durability. The standard surface may be anodized or polished, and custom material grades are available upon request.Q: How does the honeycomb/core grid design improve system performance?

A: The 6 mm honeycomb/core grid structure straightens and distributes the flow evenly, minimizing turbulence, pressure losses, and vibration, thus improving the efficiency of flow meters and other downstream equipment.Q: Is customization possible for different installation requirements?

A: Yes, custom sizes and configurations can be provided to suit diverse installation needs, ensuring compatibility with various system specifications and standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry